What is the Working Process of a Flow Switch?

856

0

·

2020/10/06

·

2 mins read

☕

WriterShelf™ is a unique multiple pen name blogging and forum platform. Protect relationships and your privacy. Take your writing in new directions. ** Join WriterShelf**

WriterShelf™ is an open writing platform. The views, information and opinions in this article are those of the author.

Article info

Categories:

⟩

⟩

Tags:

Date:

Published: 2020/10/06 - Updated: 2020/10/07

Total: 400 words

Like

or Dislike

More from this author

More to explore

A flow switch is a machine-like device. It is utilized to control and screen the flow rate of air, steam, or liquid. These are called flow sensors or flow detectors. They are used in equipment that has a constant flow of material. Water sprinkler systems, chlorination of a swimming pool, and hot water heating systems are good examples.

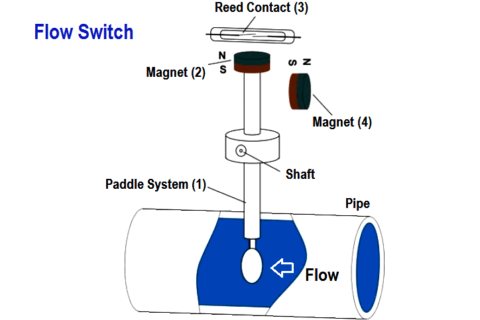

Process of a flow switch

Most flow switches consist of a paddle or a magnetic trigger. The trigger is joined to the circuit and positioned in the channel where the steam or gas passes. The paddle linked to the level is suspended in the liquid. This reed is revolved by the substance that is flowing. In terms of no liquid or static liquid, the spring expands and presses the magnet downward. The paddle transmits signal analysis to a subordinate unit called a transducer.

The transducer uses the signal from the paddle, takes it to a transmitter in a readable style. Readings are combined and adjusted to make the required signals. Calculations of the flow rates are crucial. It occurs through calculations of velocity, which relies on the liquid's pressure differential through the pipe. The cross-sectional area of the conduit process of the flow switch is well known and does not change. The velocity is a good sign of the flow rate.

Other flow switches do not have a physical paddle. They, therefore, work by bouncing a signal back off the medium being observed.

Flow switch and uses

A vane operated flow switch

It is dependent on fluid pushing against an inner paddle. As the flow falls to the pre-planned level, it activates an internal magnetic field. Mechanical and coupling switch the levers. It, in turn, trips the switch.

A variable area flow switch

It has an internal piston that triggers the control. The flow enters a port and adds pressure to the magnetic poppet. Once this pressure hits the preset level, the button turns off.

Ultrasonic flow switch

It is attached to an outside of a pipe. The ultrasonic sensors send signals when detecting a change in the flow.

Conclusion

A flow switch is crucial. The flow systems give the best results in any form of the systems they are used. It helps pump protection, cooling circuit protection, and regulating high or low flow rates of substances. They are useful in different types of equipment. Airflow switches are used in clean filters.